It wouldn’t be an exaggeration to say that creating your own brand and launching it on the market is incredibly simple these days. Of course, you don’t have to do it alone – it’s crucial that you can, and actually should, have the support of specialists in this regard, especially given the rapid growth of e-commerce.

- How to choose a manufacturing partner and why is it so important?

- Designing packaging for a new brand – what do you need to know?

Thanks to the development of the internet, consumer openness to new brands, and so-called contract manufacturing, you don’t have to worry about the enormous amount of money that would be required to build a factory from scratch just to start selling anything. Today, you can use the services of factories that are eager to collaborate with new brands. The question is, how can you stand out? Read on and learn more!

How to choose a manufacturing partner and why is it so important?

The success of a product is largely determined by its packaging. It’s what attracts the customer’s attention and builds the image. Therefore, it’s safe to say that it has a real impact on a potential customer’s purchasing decisions. It’s crucial that the private label packaging development process is carefully planned, and to achieve this, it’s a good idea to hire specialists who know their stuff best. This can significantly shorten your product’s time to market, but not only that. Cost optimization and effective differentiation from the competition are also crucial. Here’s how to do this wisely and significantly increase your chances of success. Key tips can help you:

- choose a sustainable plastic packaging supplier with experience,

- choose a company offering comprehensive packaging design and prototyping services,

Check if the partner operates as a custom HDPE bottle manufacturer.

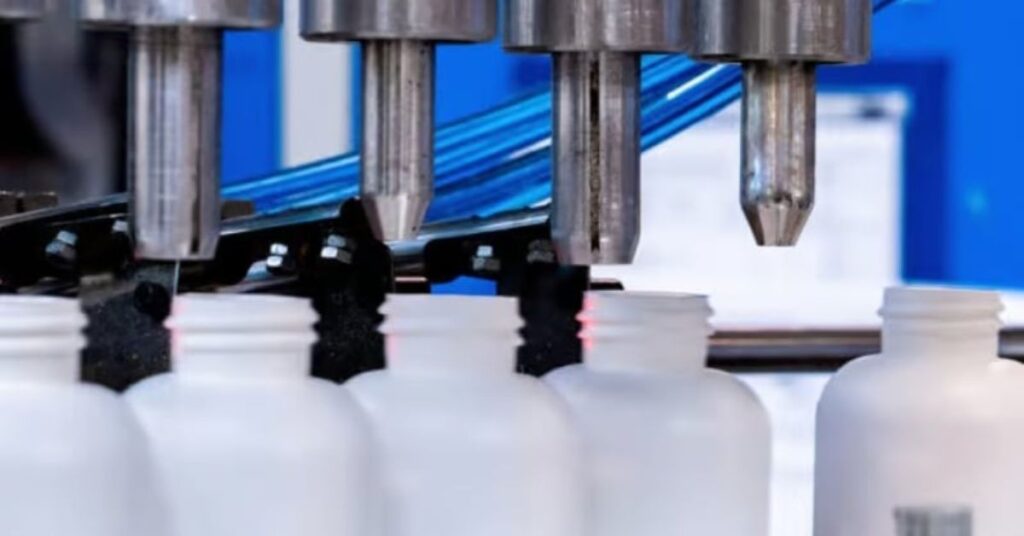

If you choose an experienced company, you can be sure of adequate technological support. An experienced production partner will not only produce the packaging you need but will also advise you on the right material, verify regulatory compliance, and ensure cost optimization.

With packaging design and prototyping services, you can count on rapid concept testing. Companies often offer a wide range of options, from 3D visualization to physical prototypes. This allows you to test the packaging before mass production, paying attention to functionality, aesthetics, and ergonomics, among other things.

If you choose a custom HDPE bottle manufacturer, you can also enjoy unique packaging tailored to your needs and brand identity. You can always modify the existing form. The possibilities are truly endless.

Designing packaging for a new brand – what do you need to know?

The foundation of packaging design isn’t just about looking good. It must also meet standards and simply sell. Compliance with regulations is particularly important in the cosmetics and household chemicals industries.

It’s important to choose a company that will help you at every stage of market entry. With them, you can count on, among other things:

- high-quality injection molded caps and closures,

- closures (child-resistant) packaging,

- rHDPE bottles for household chemicals,

- rPET bottles for personal care products.

All these elements are crucial, because not only the packaging’s tightness is crucial, but also the environmentally friendly nature of the material. However, something else matters: the ability to use recycled materials to meet growing customer needs. The number of such companies is growing, and a prime example is Rosinski Packaging Product Catalogue, a company specializing in creating packaging from recycled materials. Modern COEX multilayer packaging solutions allow for the creation of truly diverse packaging, even those with high chemical resistance. Thanks to these methods, private label packaging development can be both fast, effective, and sustainable.

Also Read: Portar Leisa: The Hidden Path to Wellness, Identity & Growth.